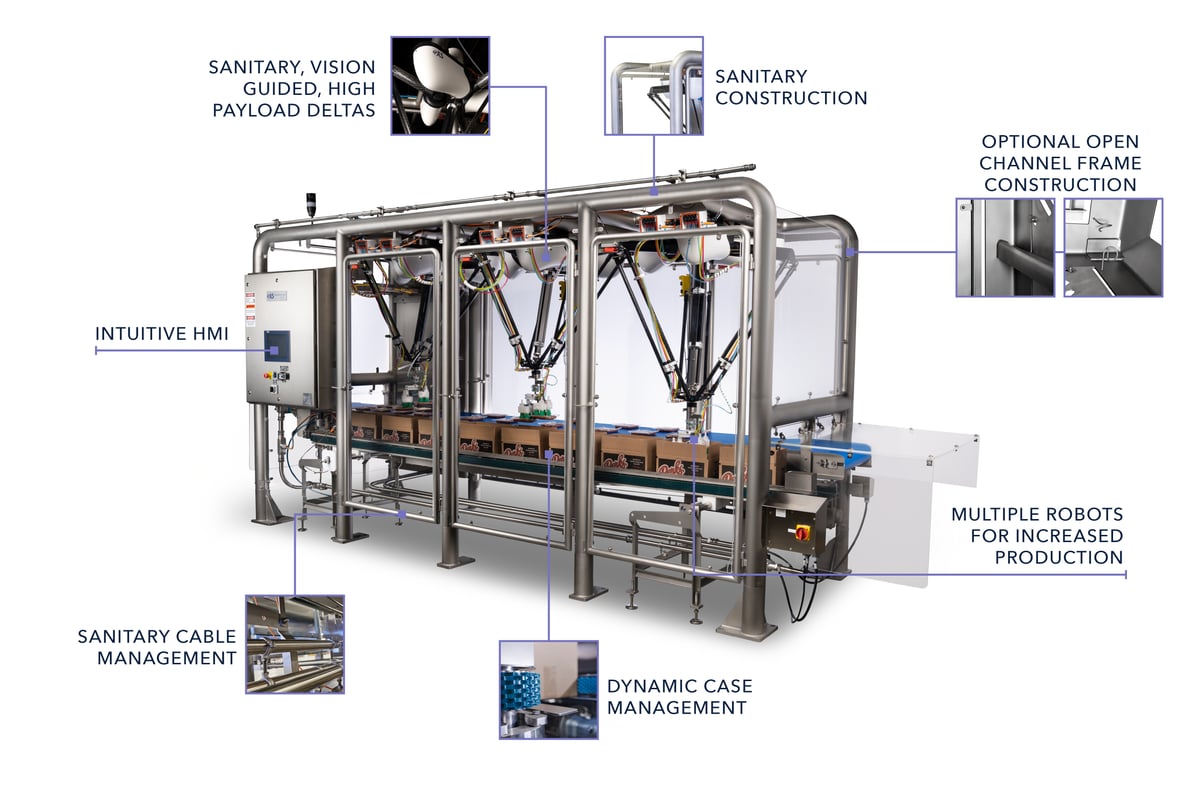

Osprey Case Packers are an essential part of the modern packaging industry. These advanced machines are designed to streamline the process of packing products into cases, ensuring that the job is done efficiently and accurately. Osprey Case Packers are known for their durability and flexibility, allowing companies to handle a variety of product types and packaging styles. Whether it’s food, beverage, or consumer goods, these machines provide a reliable solution for businesses looking to improve their packing process.

The Role of Case Packing Systems in Automation

In today’s fast-paced world, Case packing systems play a vital role in automating packaging operations. These systems are designed to handle high volumes of products, significantly reducing the need for manual labor. By automating the packing process, businesses can increase productivity and maintain consistency in their packaging. Case packing systems also enhance the overall efficiency of operations by minimizing human error and ensuring that products are securely packed. This leads to better product protection during transportation and storage.

Versatility and Customization in Osprey Case Packer

One of the standout features of Osprey Case Packer is their versatility. These machines can be customized to meet the specific needs of a business, regardless of the product size or packaging requirements. With adjustable settings, Osprey Case Packer can handle different case sizes, ensuring that products are packed tightly and securely. This level of customization makes these case packers an attractive option for industries that deal with varying packaging needs, offering both flexibility and reliability in one solution.

Benefits of Using Case Packing Systems in the Food Industry

The food industry greatly benefits from case packing systems, especially when dealing with high-volume production. These systems ensure that products such as canned goods, beverages, and packaged foods are packed consistently and efficiently. By using advanced technology, case packing systems can accommodate different packaging materials, including cartons, trays, and bags. This adaptability is crucial for businesses that need to pack a wide range of products while maintaining hygiene and safety standards throughout the process.

Why Osprey Case Packer Are Ideal for Consumer Goods

For companies in the consumer goods sector, Osprey Case Packers offers a solution that combines speed, precision, and reliability. The ability to handle various product types, from delicate items to bulky goods, makes these machines a go-to choice for many manufacturers. By integrating Osprey Case Packers into their production lines, businesses can improve their packaging operations, reduce waste, and increase throughput. These benefits are especially valuable in industries where timely delivery and packaging integrity are crucial.

How Case Packing Systems Improve Business Efficiency

Case packing systems are designed to optimize business operations by reducing downtime and maximizing throughput. With automated systems in place, businesses can keep up with demand and ensure that their products are packaged quickly and efficiently. Additionally, case-packing systems allow companies to reduce labor costs by automating repetitive tasks. This not only saves time but also ensures that the packaging process is consistent, leading to better overall product quality and customer satisfaction.

Conclusion

In conclusion, Osprey Case Packers and case packing systems represent the future of the packaging industry. Their ability to automate the packing process, handle various product types, and ensure consistent packaging quality makes them invaluable tools for businesses across multiple industries. By investing in these systems, companies can enhance their production capabilities, reduce operational costs, and meet the demands of an increasingly competitive market. With ongoing advancements in packaging technology, Osprey Case Packers is set to continue leading the way in efficient and reliable packaging solutions.